FAQ - Microball answers all your questions:

What types of ball valves are there?

Ball valves mainly differ in terms of the bore size (full bore or reduced bore) and the ball mounting. In a floating ball valve, the ball is pressed against the seal by the medium pressure, whereas in a trunnion-mounted ball valve, the ball is fixed in place and the seal is pressed against the ball.

The ball’s bore also varies: classic 2-way ball valves simply open or close the flow, 3-way models with L- or T-shaped bores enable flow diversion, and multi-way ball valves with more complex bores offer advanced control options. This flexibility allows ball valves to adapt

to different flow control requirements.

Where are ball valves used?

Ball valves are used in numerous fields where liquids or gases need

to be reliably shut off or regulated. Typical applications are found

in industry, heating and sanitary systems, hydraulics, and chemical

plants. Ball valves are also valued in household appliances and food

technology for their tight sealing, durability, and ease of use.

How does a ball valve work?

A ball valve controls the flow of liquids or gases using a ball housed inside – the so-called shut-off element. This ball is usually drilled through: when the hole is aligned with the flow direction, the medium can pass through freely. When the valve handle is turned 90 degrees, the solid side of the ball blocks the opening, reliably stopping the flow.

Ball valves are characterized by their simple operation, tight shut-off,

and the ability to switch between “open” and “closed” positions with

just a quarter turn. This makes them particularly low-maintenance

and versatile, suitable for everything from industrial systems to

household installations.

Balls for Ball Valves

Precision and Efficiency in Flow Control

Ball valves are indispensable fittings used to control and shut off fluids. Inside, there is a specially machined ball — often a drilled ball serving as

the shut-off element — that ensures a high flow coefficient and excellent tightness due to its design. The compact construction of these balls also enables small dimensions while maintaining high functional reliability.

For larger pipe diameters, ball plugs are often used, fulfilling similar functions. Ball valves are mainly used as shut-off valves and are often mistakenly referred to as "ball valves" due to the English term “ball valve.” Unlike other valves, ball valves close completely within a quarter turn (90°), enabling quick and reliable flow control.

Regular maintenance and targeted replacement of wear parts are essential to extend the service life of ball valves and ensure their long-lasting tightness. microball GmbH is happy to assist you in selecting the optimal balls for your application.

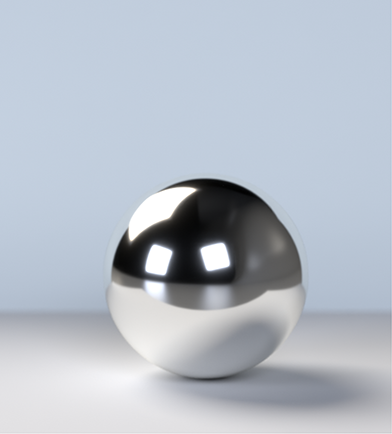

Stainless Steel Balls for Ball Valves

Stainless steel balls are robust shut-off components with

high resistance, making them ideally suited for use in ball

valves. They are characterized by their rust-free properties

and ease of machining, allowing flexible adaptation to various

application requirements. Furthermore, they impress with their

high resistance to water and aggressive media — qualities that

significantly enhance their durability and reliability in ball valves.

Plastic Balls for Ball Valves

Plastic balls are robust and lightweight shut-off components

designed for demanding conditions and are used in ball valves

when especially aggressive media need to be conveyed.

They offer the advantages of low weight and high chemical

resistance. Additionally, they are neither electrically conductive

nor magnetic, which further facilitates their safe and effective

use in sensitive applications.

Machined Balls

Drilled and machined balls offer flexible solutions for precise flow

control and shut-off technology. In ball valves, drilled balls enable

targeted regulation of fluid flow, as the bore allows a defined

flow rate — particularly advantageous for varying flow volumes.

Additionally, machined variants such as flattened or grooved balls

are used to meet specific requirements for sealing performance

and flow behavior. Both types impress with shape stability,

durability, and reliable function in valve technology.

Submit Request

Request Now

If you have any questions or can't find the

right material, feel free to contact us –

as a provider of grinding balls, we will find the ideal solution together.

Contact

Do you have questions about our products, features, or would you like an initial consultation without any obligation?

Feel free to contact us!